Dispensing: flexible, fast, accurate

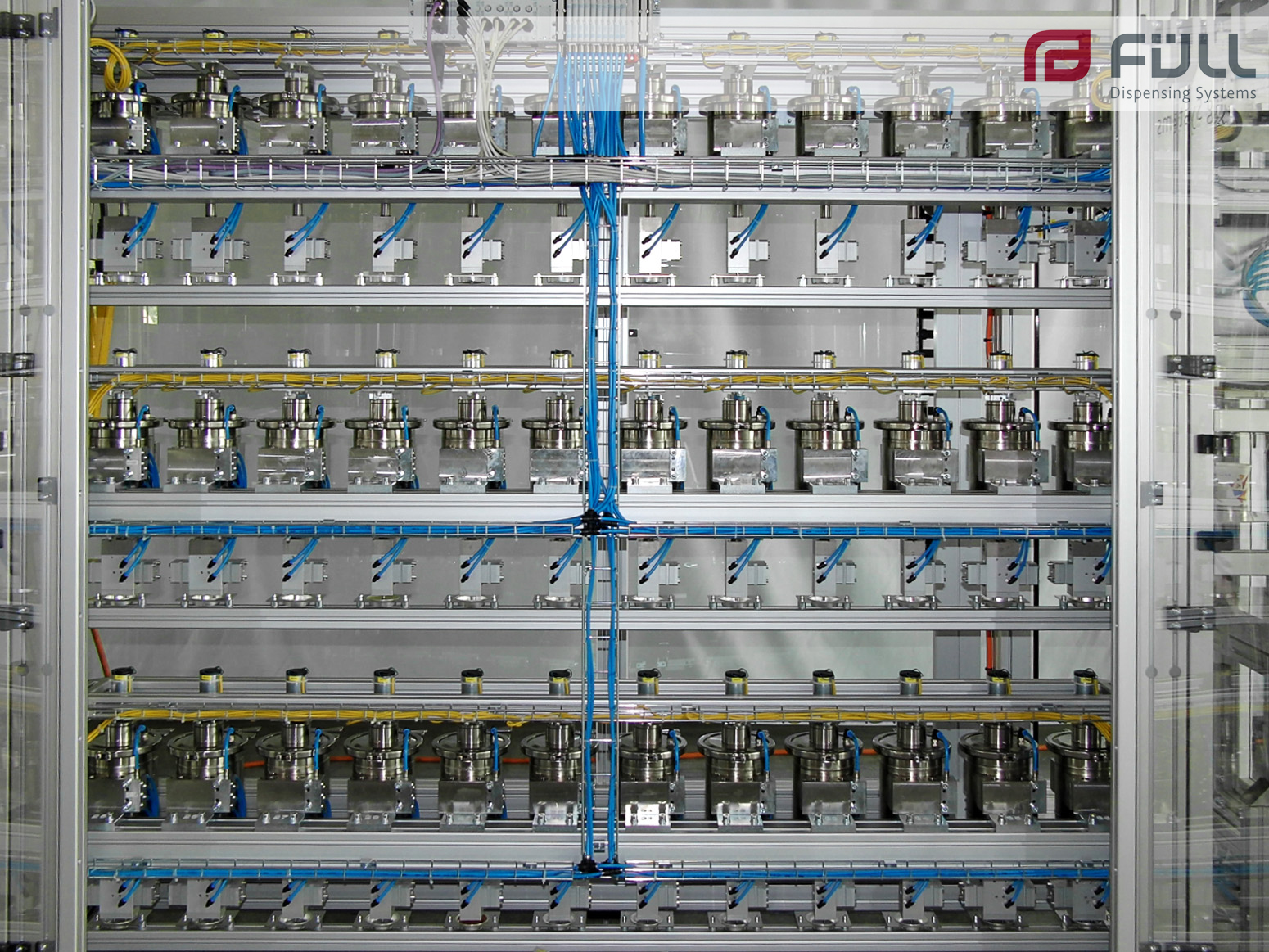

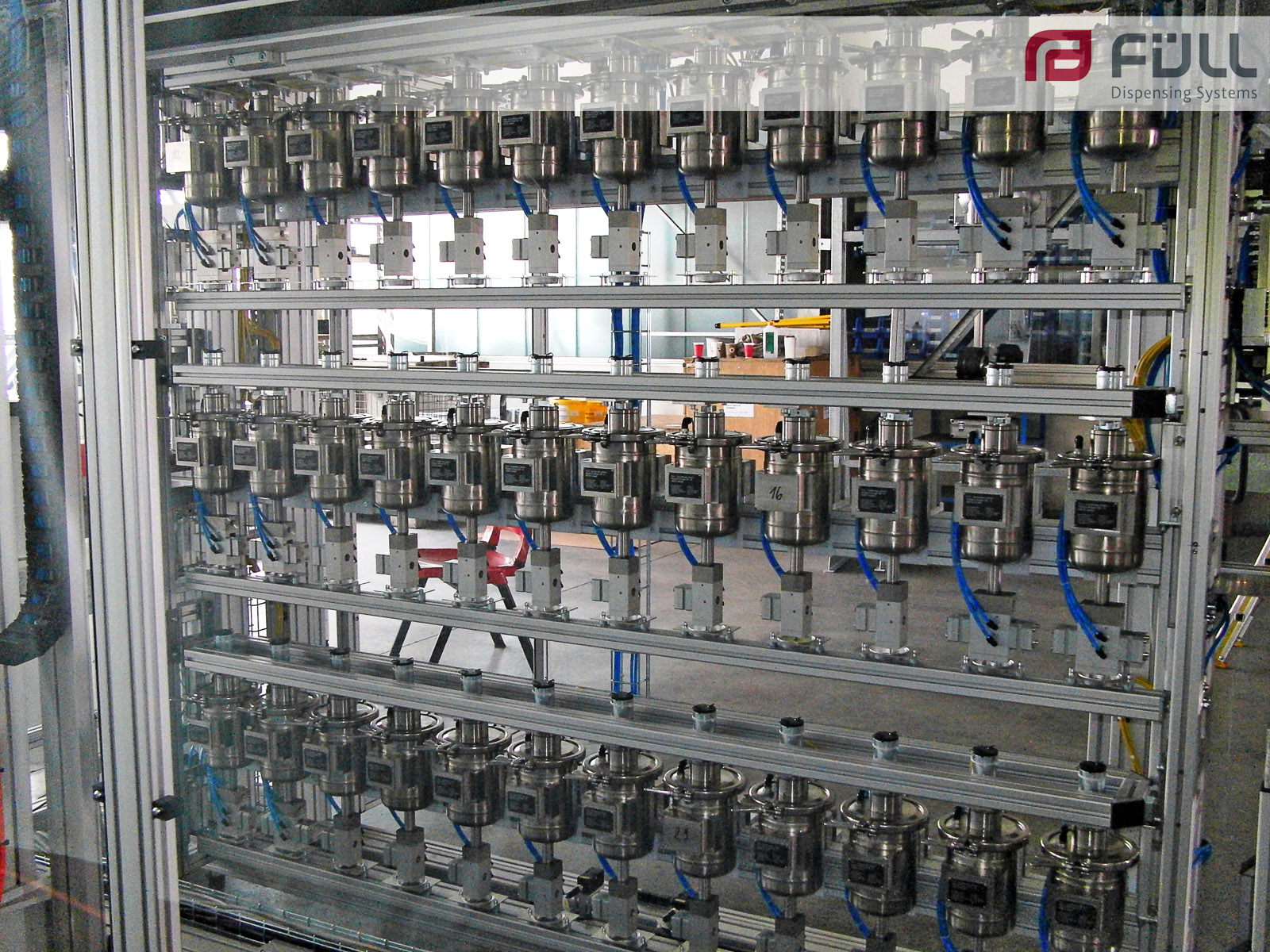

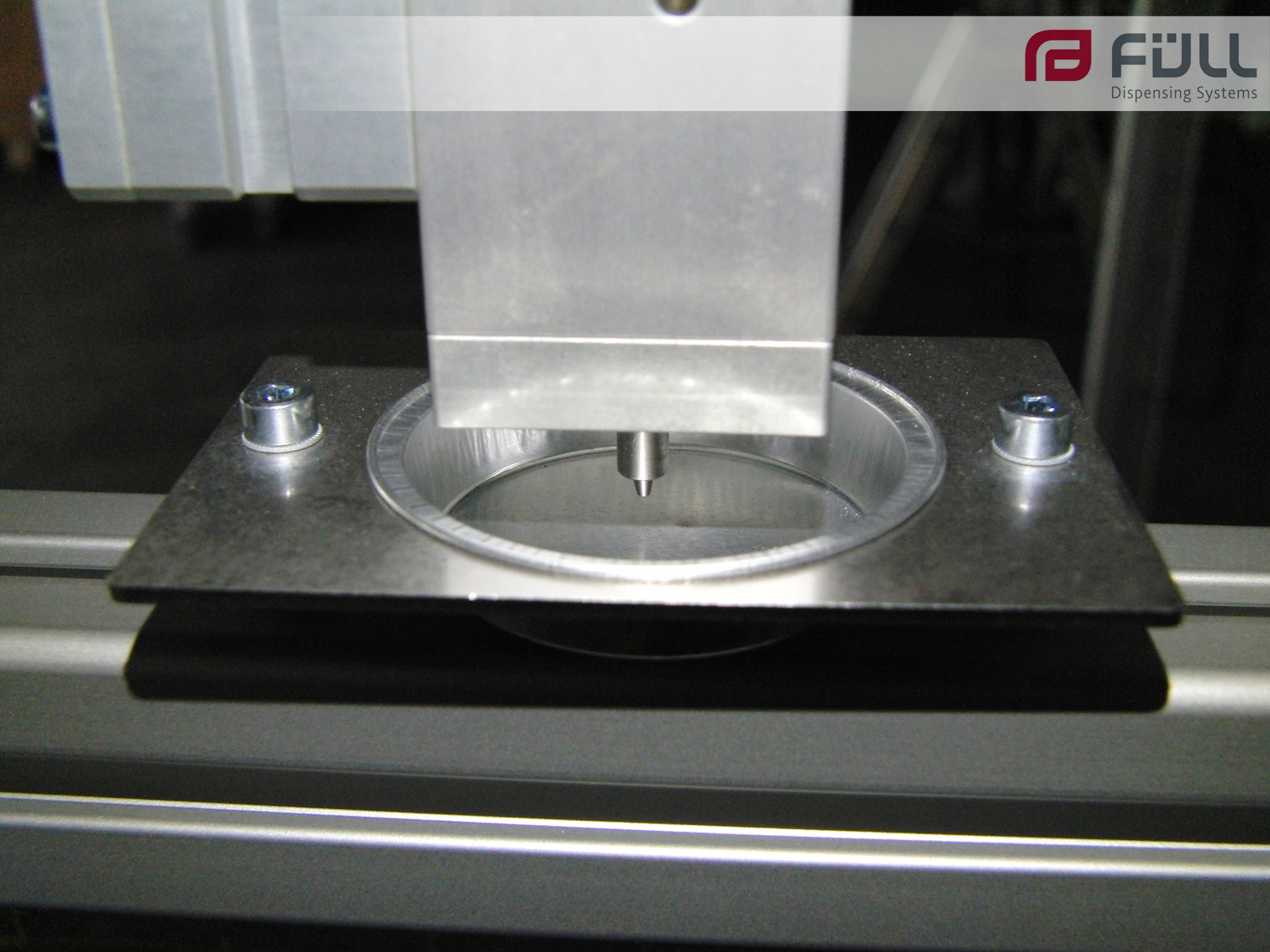

Dispensing plants provide highest reproducibility for each individual formulation component of any tinted product in desired quantity and shortest dispensing time.

- Just-in-time manufacturing of any tinted product

- Minimizing capital expenditure by reducing total storage volume

- Producing big volumes of tinted products on a compact dispensing system

- Increasing flexibility and performance